SIGMA GEO offers electrical exploration survey using the 3D TEM method to solve oil and gas exploration problems (research depth up to 4-6 kilometers).

About technology

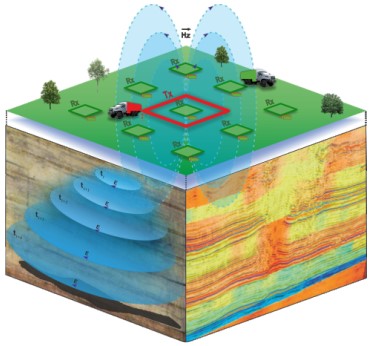

3D TEM is an area modification of a transient electromagnetic method (TEM) in the near-field zone - a pulse-controlled source method based on the study of a transient processes which is excited when the current in the source changes.

3D TEM is an area modification of a transient electromagnetic method (TEM) in the near-field zone - a pulse-controlled source method based on the study of a transient processes which is excited when the current in the source changes.

3D TEM soundings are carried out at the exploration and producing stages of geological exploration.

Geological problems to be solved |

|

|

|

|

|

|

|

|

|

|

|

Methods of field work, equipment and facilities

Generally, field electrical prospecting work using the 3D seismic survey method is carried out using a network of 3D CDPM seismic profiles; any roads available in the area are also taken into account: rural, forest, logging and others.

The parameters of the 3D TEM observation technique may vary depending on the characteristics of the experimental site and the geological tasks.

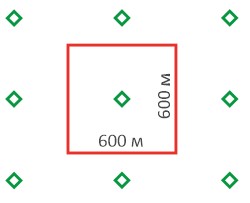

One example: nine-spaced stations with square transmitter (600 x 600 m) and receiving (18 x 18 m, 29 turns) loops, current in the transmitter loop up to 250 A.

Example of a nine-spaced 3D TEM station

When carrying out 3D TEM field work, digital telemetric electrical exploration stations SGS-TEM are used.

|

Measuring devices SGS-TEM |

Transistor current switch SGS-CTU300 |

Optimal configuration of a fielded party:

|

|

|

|

|

|

|

|

The average productivity of one fielded party per month is more than 152 km2 of the 3D TEM.

In-office studies

Electromagnetic data processing is carried out in the modern TEM-Processing program, which includes statistical and robust signal accumulation methods, as well as a set of specialized frequency filtering algorithms, including noise reduction of a high-line frequency 50 hz.

Quantitative interpretation of signals is performed in the Model software package, based on algorithms for solving forward and inverse problems developed at the Institute of Petroleum Geology and Geophysics SB RAS.

Quality control

According to the requirements of the Electrical Prospecting Instructions, control observations are carried out without fail in the amount of 5% of the total number of planned observations. However, for additional control at both the field and in-office stages of work, quality assessment is performed using advanced software:

According to the requirements of the Electrical Prospecting Instructions, control observations are carried out without fail in the amount of 5% of the total number of planned observations. However, for additional control at both the field and in-office stages of work, quality assessment is performed using advanced software:

- EMQC - a comprehensive system for assessing data quality, which allows to automatically perform quality control of the material and quickly identify data complicated by electromagnetic interference, anomalous and substandard curves based on quantitative QC quality indicators.

- EMIQ - specialized software for assessing the quality of interpretation of sTEM and TEM materials.

The effect of using the 3D TEM technique

- Increased probability of geological success (in case of integration seismic and electrical prospecting using the TEM method);

- Reducing the risk of drilling non-productive wells;

- Ability to calculate resources/reserves;

- Minimizing the risk of emergency drilling by mapping the intervals of ALRP и AHRP;

- Optimization of designs and locations of wells, including within the framework of the technological scheme for field development.

SIGMA-GEO work experience using the 3D TEM method

- More than 12,000 km2 3D TEM have been completed

- More than 60,000 physical observations of 3D TEM

- Work using the 3D TEM method has been tested in various climatic, geographical and geological conditions; the effectiveness of the predictions has been repeatedly confirmed by drilling.